REBUILDING AN AMERICAN CLASSIC

Gumption – The Mind’s Gasoline

Building a bike for TROG was real when the title of the 1937 Flathead was in my hand and I legally owned a bunch of parts that could be a bike. It was in that moment that this build became more than just a crazy idea. I had never done anything like this, but whether I was ready or not, I was about to build a bike from the bones I had acquired. This bike had to be built from the ground up, and I didn’t even have all the pieces I needed.

It was time to review all that had to happen. Within the next 65 days, I had to build a 1937 Flathead with all original parts. That meant acquiring the remaining parts from Jeff Coffman, rebuilding the engine, rebuilding the transmission, applying to The Race Of Gentlemen, and concluding the project by riding the bike across the country from Pennsylvania to Seattle. It was a lot to fit into our short time-frame, but my dreams and reality, as usual, were tossed into a blender to produce my own delusional reality.

Seattle to Pennsylvania

I helped Ryan disassemble the bike while I was in PA and we made a list of everything that was needed. A gas tank, oil tank, tins, seat, and a slew of engine and transmission parts. The goal was to use purely 1937 Harley Davidson parts for everything we possibly could. In order to get approved for the Race of Gentlemen, this bike had to be authentic.

Back to Washington & Oregon

I shot the list of what we needed to Jeff Coffman before I flew back to Seattle. After being home for a few days I ripped down to Oregon to see what I could wheel and deal for the rare parts we needed.

The day with Jeff at his shop was like going back to school. After about 8 hours of the “history and shop class,” I had a lot of the parts we needed: a 1937 gas tank, 1937 oil tank, 1937 front and rear tins, and a handlebar that was broken into pieces. Each piece had a life of wear to them, and each piece was completely authentic. I drove away from Jeff’s with a gold mine of 1937 Harley Davidson parts. The next day, everything was shipped off to PA.

I had something special in mind for the seat and p-pad. I found two seat pans to cover; an original Bates pan for the race, and an original Harley Davidson solo seat just for fun. I reached out to Horween to get some special leather and they scored us some old stock calfskin they still had from 1940. After that, I connected with “Ginger McCabe from New Church Moto in Oregon. Her artful touch, combined with priceless 70 year old leather, made for the perfect bike seat. I put the seats in my bag, and was off to Pennsylvania for the second time.

Back to Pennsylvania

Now that we had everything, it was time to start designing and building. For the frame, forks, and tank, we made some small structural repairs, and simply cleared each part to preserve the metals natural character. We wanted to celebrate the fact that these pieces were authentic. The only parts we chopped and customized were our 1937 fenders. We popped off the supports, cut 2 inches out of the center, and trimmed the sides at the bead roll. The age of each metal part, and even the bronze braising on the frame, was preserved in its natural state after 80 years.

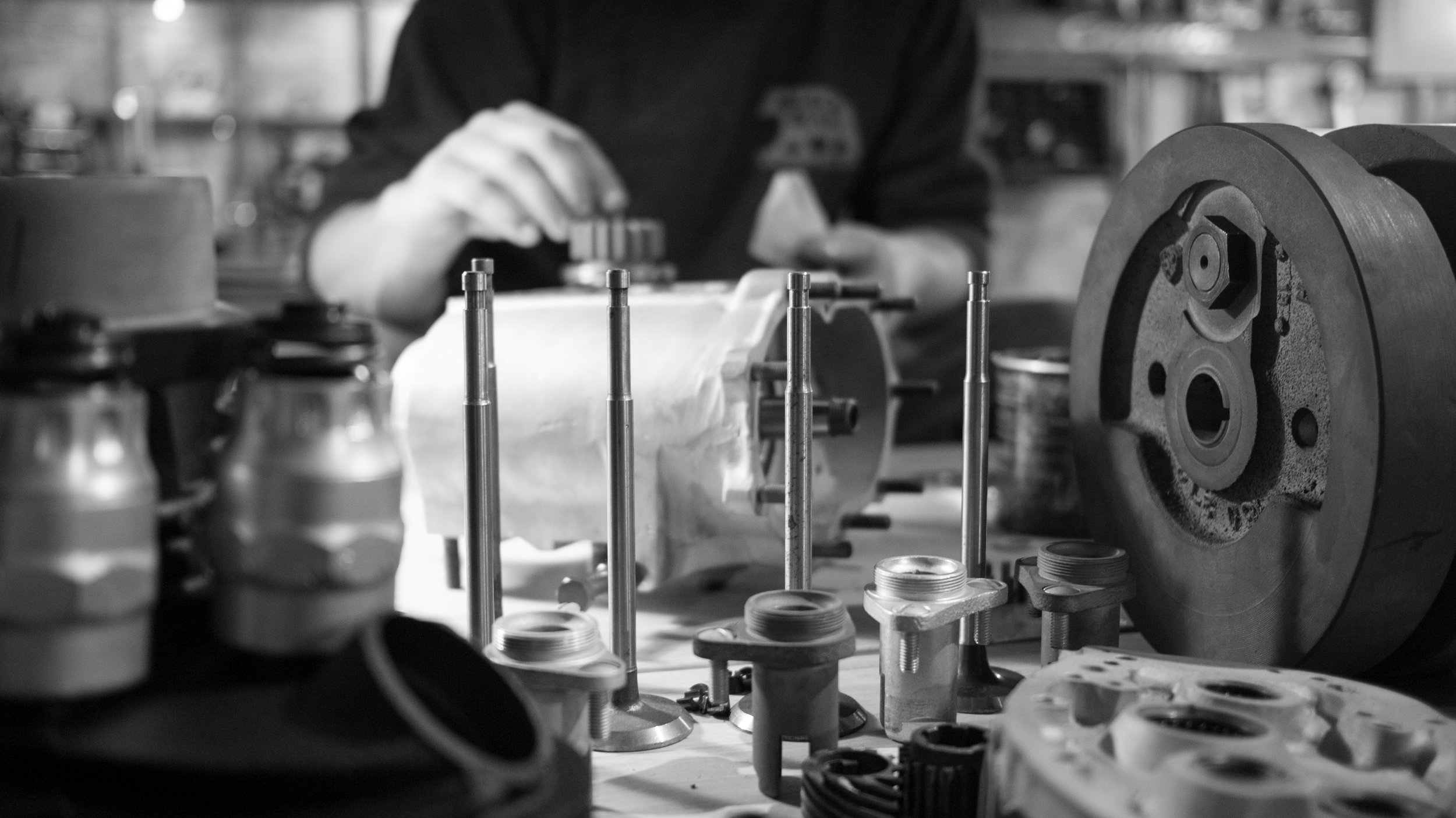

From there we moved on to the important stuff; our engine and transmission. Ryan has plenty of experience rebuilding hot rod engines, but this would be his first Harley engine and transmission. Relying on him to do this seemed crazy at first glance, but his natural talent and understanding of engines made for a successful build. Having Ryan re-build the bike gave me the opportunity to help out where I could, document the process, and make it a more personal engagement. We rebuilt the engine as well as the transmission, working day and night to meet our deadline. In the end we managed to meet the requirements given by the Race of Gentlemen. Our application was in and I couldn’t be more excited with how the bike was coming along.

Looking back at every part of this, I laugh at my initial willingness to dive right into this project. I had no idea what I was getting myself into, but nevertheless, we had accomplished our goal. What Ryan did for the brand, as well as this story, is on another level. I found and sourced the parts that were necessary, but it was his expertise that made it all possible. He championed a complete engine rebuild, and although most of it was over my head, together we made it happen. The process was documented, and I was able to help in the final assembly of the bike. Personally placing the newly built engine into the frame, I knew we had made something truly amazing. This build ended up being one hell of an experience for all of us.